LPP Fusion continues to make progress in perfecting the larger Anodes. This catches us up and we may soon se a jump in performance and overall consistancy. It also shows us just how painful and slow every step happens to be.

At least we are moving forward and that is good. A bigger budget would tackle an even larger anode system concurrently.

This program is at least not trying to play quiet which would be bad. The infection of secrecy has not taken hold.

Kapton Armors the Switches

The LPPFusion team is closing in on the design that will prevent all undesired breakdowns in the switches. The key is a two-layer defense-in-depth covering the metal surfaces with adhesive Kapton film, protected by the sealed Teflon disks.

In August, the Teflon disks sealed against the copper had protected against vertical breakdowns in the switches that led to pre-fires. But as the LPPFusion team reduced the pressure in the switches to seek faster firing, the breakdowns recurred. Now, the Kapton film, sealed by adhesive to the copper, has stopped the breakdowns even at the lowest pressures needed. The seal prevents gas from reaching the copper at any point, except the exposed electrodes where the breakdown is supposed to occur. In turn, the Teflon disks prevent gas from reaching the Kapton film, protecting it against chemical erosion.

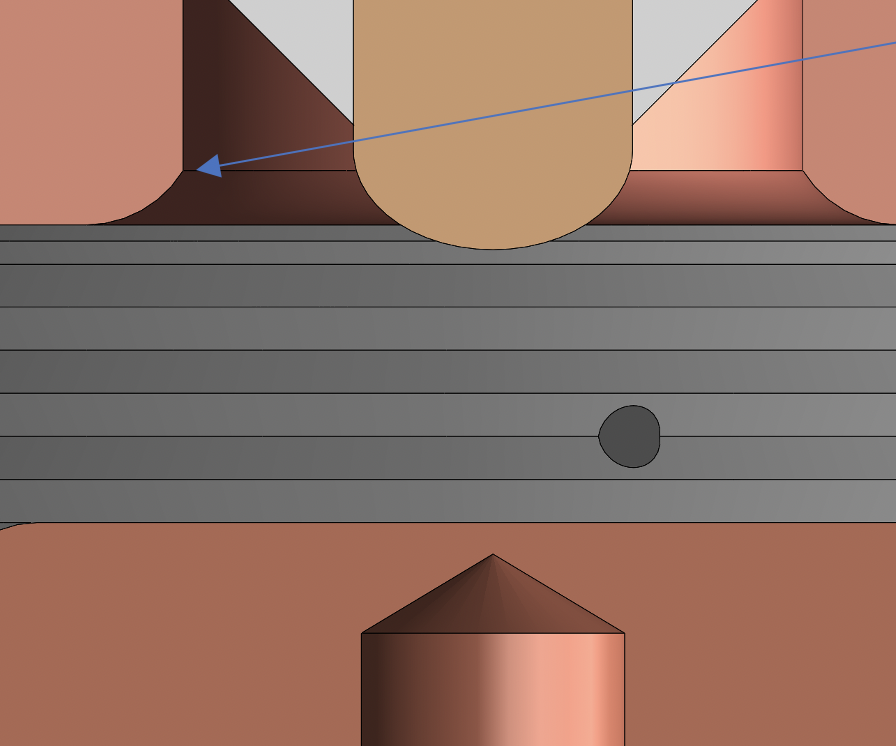

The final step in implementing this new design is in applying it to the horizonal breakdown that occurs when the negative trigger voltage appears on the central pin (see Figure.1). The horizontal breakdown to the outer electrode can occur before the intended vertical breakdown that starts the current flowing. This produces a negative current that contributes to the disruption of the filaments in our FF-2B fusion device. To stop this breakdown, we are putting the same Kapton and Teflon armor on the inner surface of the top electrode. This will be ready for testing in October, hopefully leading to resuming firing with functional switches in November.

Figure 1. Horizontal breakdown between the top electrode (arrow) and the central pin (beige) prevents proper switch functioning. The intended breakdown is between the central pin and the bottom electrode (lower copper-colored strip) which releases the charge in the capacitor. Current then rapidly jumps over to connect the top and bottom electrodes to complete the circuit. To prevent the horizontal breakdown, we are armoring the inner radius of the top electrode with Kapton and Teflon.

With Kapton on our switches and beryllium in our central FF-2B electrodes, LPPFusion is using the same key materials as does the James Webb Space Telescope, which has been producing such revolutionary results in astrophysics. JWST uses Kapton film for the five layers of its big solar shield and beryllium for its 6.5 meter mirror.

We at LPPFusion share our supporters’ frustration that fixing the switches is taking so long. But this is mainly a result of our continued staff shortages. In turn, hiring more staff is depending on a greater level of capital fund-raising. To fix this crucial problem, we are aiming immediately to maintain a fundraising level of $100,000 per month, $1.2 million per year, to almost double our funds available. Our goal of achieving $500,000 from Wefunder by October 31 is part of this immediate objective. Our medium-term goal is to achieve $2 million per year.

These goals are achievable with the help of our supporters. Our reports, videos and social media posts are regularly seen by over 20,000 people a month. If just half of our readers invested in one share, $200, per year, we would reach $2 million per year. That’s 55 cent per day, one latte a week.

No comments:

Post a Comment