We have had 3D printing for a long time now, but it has been mostly limited naturally to prototyping which is no surprise.

Now we have a legitimate killer app. Any knowledge of titanium metalurgy tells you are usually working somthing that is almost impossible. Usually small scale because machining failure rate is huge. It is enough to know that you have one pass and any error is machine hardened and unworkabvle

suddenly it is possible to imagine a massive structure been printed and hardened up. We could build bridges out of titanium!

Let us strat with printed titanium bolts.

New titanium alloy has highest specific strength of any 3D-printed metal

September 19, 2022

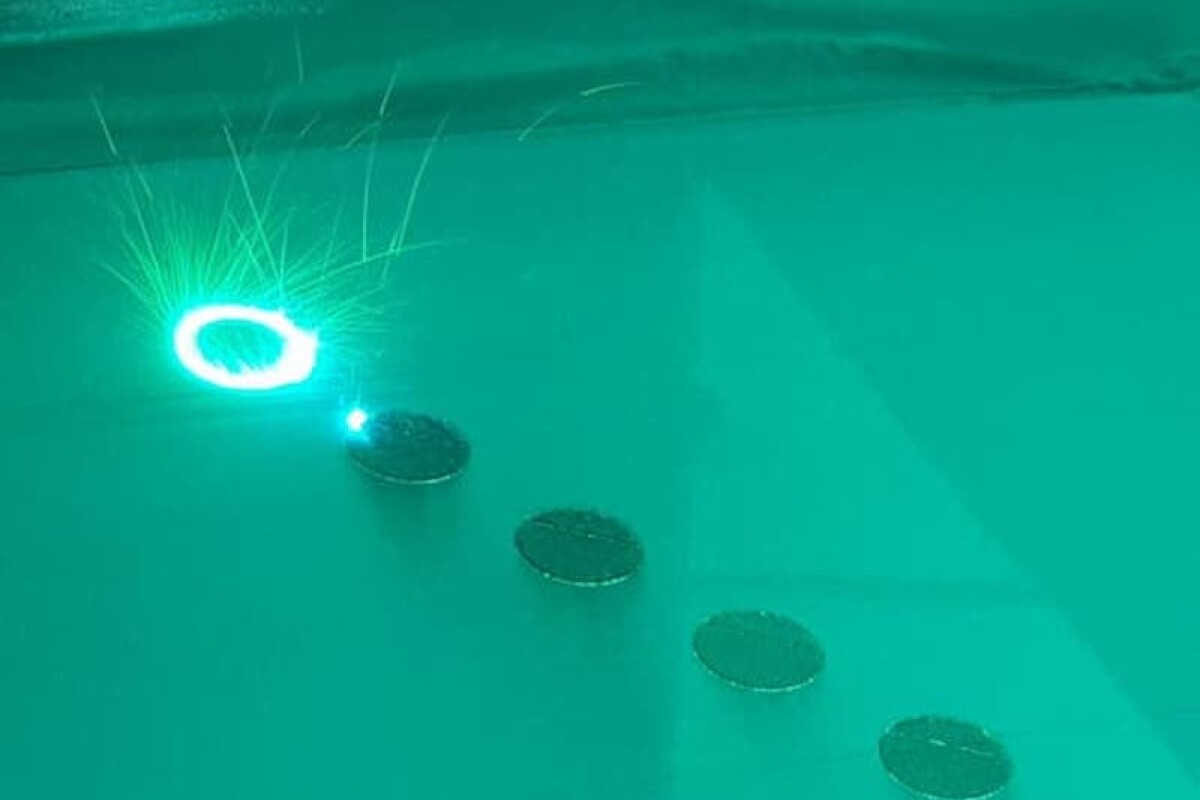

The new titanium alloy being 3D printed through a laser powder bed fusion technique

Monash University

Engineers at Monash University have developed a new 3D-printable titanium alloy with a unique microstructure that makes it ultra-strong. Not only is it stronger than most other forms of titanium, but it has the highest strength-to-weight ratio of any 3D-printed metal ever made.

Titanium alloys are already prized in industry thanks to their strength and relatively light weight, which makes them perfect for aircraft and other vehicles. But there’s always room for improvement, and the new Monash alloy not only boasts greater strength, but because it’s 3D printed, it’s much easier to make into whatever shape is needed.

The team starts with a common 3D printing technique where a bed of powdered metal is melted by a laser, fusing it into a solid layer by layer. In this case, that powdered metal is the commonly used beta-titanium alloy. Next, the material undergoes heat treatment at temperatures between 480 and 520 °C (896 and 968 °F), which produces a microstructure that gives the alloy its incredible strength.

The treatment process causes particles of titanium to precipitate together in nanograins, which merge in “nanotwin” structures that each share a common side. The team says this is the first titanium alloy to exhibit this kind of structure, and it makes it much stronger than usual.

In tests, the team demonstrated that the new titanium alloy had both elongation and tensile strengths (stretching and tension, respectively) of over 1,600 MPa. For reference, most commercial titanium alloys top out at around 1,000 MPa. This is also the highest specific strength for any other 3D-printed metal alloy, the team says.

“Our findings offer a completely new approach to precipitation strengthening in commercial alloys that can be utilized to produce real components with complex shape for load-bearing application,” said Professor Aijun Huang, lead researcher on the study. “This application is still absent for any titanium alloys to date. The 3D printing plus simple heat treatment also means the process cost is greatly reduced compared to other materials with similar strength.”

The research was published in the journal Nature Materials.

No comments:

Post a Comment