This is important and we are getting there and getting real as well. Our objective is a steady production that induces usable electrical current. The impurity problem frustrated advances on other aspects. this is now ending.

so yes, this is good news.

The switches are almost ready and we may soon see production records fall. This will be direct powerr production without shoving any thing through a heat engine. .

FF-2B Plasma Purity Sets New Record (Focus Fusion)

https://mailchi.mp/lppfusion/report-april-28-8659240?e=3eee1c4ccd

New measurements by the LPPFusion research team have confirmed that the FF-2B device has achieved a new world record for the purity of a fusion-producing plasma. The impurity levels in the plasma have decreased three-fold from that achieved in the previous 2019 experiments with beryllium electrodes and are at least ten times less than those reported for any other fusion device. In the new results, we have confirmed that less than 0.2% of the ions entering the pinch region where fusion is produced are impurities, and all of them are from light elements - just beryllium and oxygen - that affect the plasma the least.

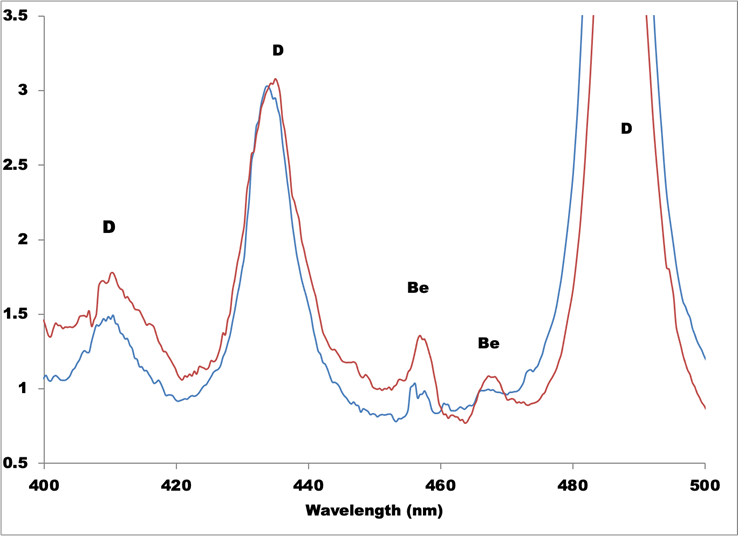

Figure 1. The new spectra (blue lines) from April 6 show the more than 3-fold decrease in the already small beryllium peaks (labeled Be) from our 2019 experiments (red line), as measured relative to the big deuterium peaks (labeled D). Combined with measurements of deposition on vacuum chamber windows, these spectra demonstrate the achievement of record low impurity levels for fusion plasma.

Reducing impurity levels has long been extremely important in fusion research. First of all, impurity elements can greatly increase radiation that cools the plasma, preventing the achievement of the high temperatures needed for fusion. The impact on the plasma increases as the square of the atomic charge (z), so heavy (high-z) ions like copper, iron, nickel and tungsten are especially damaging.

Second, the erosion processes that produce the impurities by vaporizing device components reduce their lifetime. Finally, the same erosion processes, if fast enough, can cause experimental results to deteriorate even in the course of a few months of experiments. LPPFusion’s reduction of impurity levels below any achieved elsewhere is thus a major step forward for fusion research.

LPPFusion’s new world record joins two other records we have earlier achieved. In 2016 we achieved, and published, the world record for confined ion energy of over 200 keV (the equivalent of more than 2 billion degrees, 200 times hotter than the center of the sun). That same year our FF-1 device achieved the highest ratio of fusion energy output to device energy input of any private fusion research effort. With only $9 million spent so far on our project, LPPFusion’s three records make us a world leader in the development of fusion energy.

The new advance in impurity levels was measured by two independent methods, both relying on our optical spectrometer. A spectrometer measures the distribution of light over a band of wavelengths or colors. Our instrument covers the whole optical range and a bit into the infrared and UV bands.

In the first method, we used the spectrometer to measure the thickness of material deposited on our quartz viewing windows. A layer of material that is thin enough to allow light through, absorbs short wavelength light (such as blue light) more than long wavelength light (such as red light), introducing a slope in the whole spectrum. The bigger the slope, the thicker the layer of material. By comparing the slopes with a clean window and after dozens of shots, the total rate of deposition can be measured and thus the total amount of impurities from solid material determined.

Our new FF-2B measurements, taken140 shots after our new anode was installed in 2021, show a decrease in total deposition by a factor of 2.5 compared with our results in 2019. A layer only 0.15 nm thick of material is being deposited per shot, which works out to a total impurity contribution of only 10 micrograms per shot. We know the amount of gas in the current sheath is 3.3 mg, so the Be impurity level is now no more than 0.3% by mass or 0.08% by number of ions.

A second method confirmed the reduction in impurity. We took spectra of the plasma near the top of the anode, where the current discharge begins. The spectra show “lines” or peaks of intensity at certain wavelengths that are characteristic of each element. The relative intensities of these lines allow us to compare the relative abundances of the elements. In Figure 1., we have plotted a portion of a typical spectrum from 2019 (red line, from Shot 8, June 21, 2019) with a new spectrum (blue line, from shot 1, April 6, 2022). The big peaks, labeled D, come from the deuterium fuel gas, while the small peaks, labeled Be come from beryllium vaporized into the plasma. The lines are broadened into peaks because of the relatively high pressure of the fill gas (deuterium).

The spectra are scaled in this figure so that the intensities of the deuterium peaks at 436 nm are the same. As is clear, measurement of the areas of the small beryllium peaks show that they are nearly 4 times smaller in the new spectra as in the old ones, confirming the decrease in impurities in the plasma that is compressed into the pinch (plasmoid region).

We are certain that the main source of this reduction in erosion of the beryllium prior to the pinch comes from the careful removal of the oxide layer we performed by hand-polishing before the new anode was installed in June 2021. In the previous installation in 2019, the beryllium anode had not been polished and the thin layer of oxides present on the anode was explosively ripped off by the current of the first shot. Beryllium oxide does not conduct electricity, so the current has to burst through it to get to the conducting beryllium metal underneath. This left a roughened surface that eroded faster than the smooth oxide-free surface left by the polishing. See Fig.2, republished from our October 15, 2021 report.

Figure 2. Our 2021 polished anode (left) still shined mirror-bright after three shots in August, 2021. It is viewed through a window on our vacuum chamber. The anode is a bit more than two inches in diameter. The colors on the anode seen here are the result of lighting and camera response. The true color of the anode is still silver. In contrast, our first beryllium anode after one shot in 2019 (right) was covered with a dark ”snow” of beryllium oxide dust, which was vaporized and redeposited by FF-2B’s powerful electric currents. This is what we avoided by our new polishing procedure.

Equally important, the entire spectrum from 300 nm to 800 nm shows only the lines of deuterium, beryllium, oxygen and nitrogen - no heavier elements are present at all. The nitrogen is not an impurity but is deliberately introduced as a mixing gas for experimental purposes.

The oxygen, we are sure, does not come from an external leak. The measured leak amounts to only 1/10,000th of a percent of the deuterium fill pressure. So, it must come from remaining beryllium oxide. This reservoir of oxide is present on the cathode, which was not polished in this assembly. Safety concerns about possible exposure to beryllium dust in the chamber led us to remove the old anode and insert the new one from above, without disassembling the chamber and giving us access to the cathode.

Since in beryllium oxide the oxygen has twice the mass of the beryllium, we calculate that at most 20 micrograms of oxygen are released in each shot. This is consistent with the rough indications from the relative strength of the spectral lines. Such a thin, almost monomolecular layer of oxygen will be only temporarily removed in each shot, since the oxygen will swiftly recombine chemically with the hot metallic beryllium on the surface of the electrodes. This is unlike the beryllium, which will re-deposit equally on all surfaces in the chamber, including the much colder vacuum chamber walls and windows, gradually eroding from the electrodes.

With beryllium and oxygen together, all impurities in the plasma entering the pinch region at the end of the anode (where the fusion occurs) can amount to no more than 0.16% of the ions by number and 0.5% by mass. A better measure of the impact on the plasma of these impurities is the effective atomic charge, zeff, which is only 1.03. This is a record low value for any fusion-producing plasma. The lowest zeff claimed in published papers, by the new W-7X stellarator device, is 1.3, a factor of ten higher (since impurities are measured as the difference between zeff and the 1.0 contributed by the deuterium.)

The achievement of a record plasma purity has important significance for the fusion energy research effort in three major ways. First, since the very start of the fusion energy effort, impurities have increased radiation and thus cooled plasmas. Some of the first fusion experiments ever performed were spoiled by the presence of oxygen from water vapor stuck to metal surfaces of the device. Efforts to reduce impurities, especially those caused by ubiquitous oxides, have been a main feature of just about every fusion research effort. Many other researchers using the dense plasma focus (DPF) devices, like our FF-1 and FF-2B, have been repeatedly set back by impurities caused by rapid erosion of electrodes by the concentrated currents in the DPF. Our recent advance completely eliminates impurities as a significant source of electromagnetic radiation from the plasma.

Second, in DPF devices, the concentration of dense impurities coming off the electrodes, which are millions of times denser than the surrounding plasma, caused asymmetries in the plasma sheath and disruption in the current filaments, preventing high-density plasmoids from forming. The new reduction in impurities has eliminated this headache as well (although we know that there are other factors that still disrupt the filaments.)

Finally, the same process that causes impurities in the plasma - vaporization of the electrodes - also erodes the electrodes, gradually changing their shape and causing deterioration of the fusion yield results. The new measurements show that, for experimental purposes, this process has now been eliminated as a concern. If the erosion is occurring entirely in the 1-cm band near the ceramic insulator, the erosion rate would take 180,000 shots to erode even 1 mm, so will not make any difference in the thousand shots or so we are likely to take with this anode.

In fact, there is good reason to believe that most of the beryllium we observed deposited on the windows is eroded after the pinch, from the radiation and blast wave coming from the pinch region and does not even enter into the pinch or affect the fusion process. For one thing, the beryllium lines in the spectra taken from the pinch area are 5 times as strong as those taken near the top of the anode, indicating that perhaps as much as 80% of the deposits we measure come from after the pinch. In addition, the pattern of deposits on the window is much more consistent with the material originating near the pinch region then from the anode generally. If this is the case, the impurity of the plasma entering the pinch is even lower than that we report here.

But even if the worst erosion is happening in the roughly 2 cm of the anode hole nearest to the pinch, the erosion rate would still give 250,000 shots before a mm is eroded off the anode’s tip.

There are two caveats to these good results on erosion. First, erosion is not the only threat to the lifetime of the anode. Mechanical vibrations caused by the shock of the pinch could also lead to cracking and mechanical failures. We’ll be measuring this vibration in experiments later this year. Second, while a lifetime of hundreds of thousands of shots is fine for an experimental device, in an actual fusion generator a lifetime a thousand times longer will be needed to allow monthly maintenance. We have ideas on how this further reduction can be achieved, but most of that work will have to wait until the engineering stage of development.

LPPFusion’s new advance caps years of our own work in reducing impurities. We worked to vastly reduce impurities in 2015-2016, by lengthening the chamber, (to reduce splash-back of impurities); coating the vacuum chamber with titanium oxide (much tougher to remove than stainless steel); switching from multi-part copper electrodes to monolithic tungsten electrodes (thus eliminating severe arcing between parts); baking out the chamber to remove water vapor; and again in 2019 switching in to beryllium and finally, in 2021, eliminating the initial oxygen layer on the anode. The deployment of preionization in 2015 to minimize high-energy runaway electrons near the start of the pulse was also critical in this reduction.

The transition from copper to monolithic tungsten decreased impurity by mass 3-fold, but due to tungsten’s higher z, zeff only dropped from 4 to 3. This was, however, enough to allow the achievement of our two records for fusion yield and confined ion energy in 2016. The big drop, by a factor of 30 in impurity mass and zeff, came with the switch to the far lower-z beryllium electrodes. Overall, including our recent factor-of-3 improvement, the decade-long effort reduced impurities by over 100-fold.

The LPPFusion team will be submitting the evidence for this new purity record for fusion-producing plasma to a prominent peer-reviewed journal. We’re confident our peers will recognize this latest record achieved with our FF-2B device. We are also confident it won’t be the last record we achieve.

To publicize this new major advance, we need help with the PR outreach as the news media is not adequately covering less-funded companies like LPPFusion. If you have contacts who can put this news into the mass media, or on widely-followed YouTube channels or podcasts, please reach out to them. A press release on this advance will be sent out shortly. We also appreciate your recommending us as guests to shows, for presentations or for interviews.

In the meantime, our fusion fans and supporters are no doubt wondering how we are doing with the switches. We just finished replacing all the ceramic parts with Teflon ones and will have a full update on our progress in the next LPPFusion Report. Stay tuned.

No comments:

Post a Comment