I have seen this before, but fabricated using a plywood press and suspected tgen that product yields were a problem. From the video i have seen, They use better pretreatment and it is a tighter squeeze.

And if these strength parameters also hold up, this will be a revolution in materials.

Understand that metal production all demands high temperature processing to create a clean molten end product. Obviously this cannot be done without a huge energy budget.

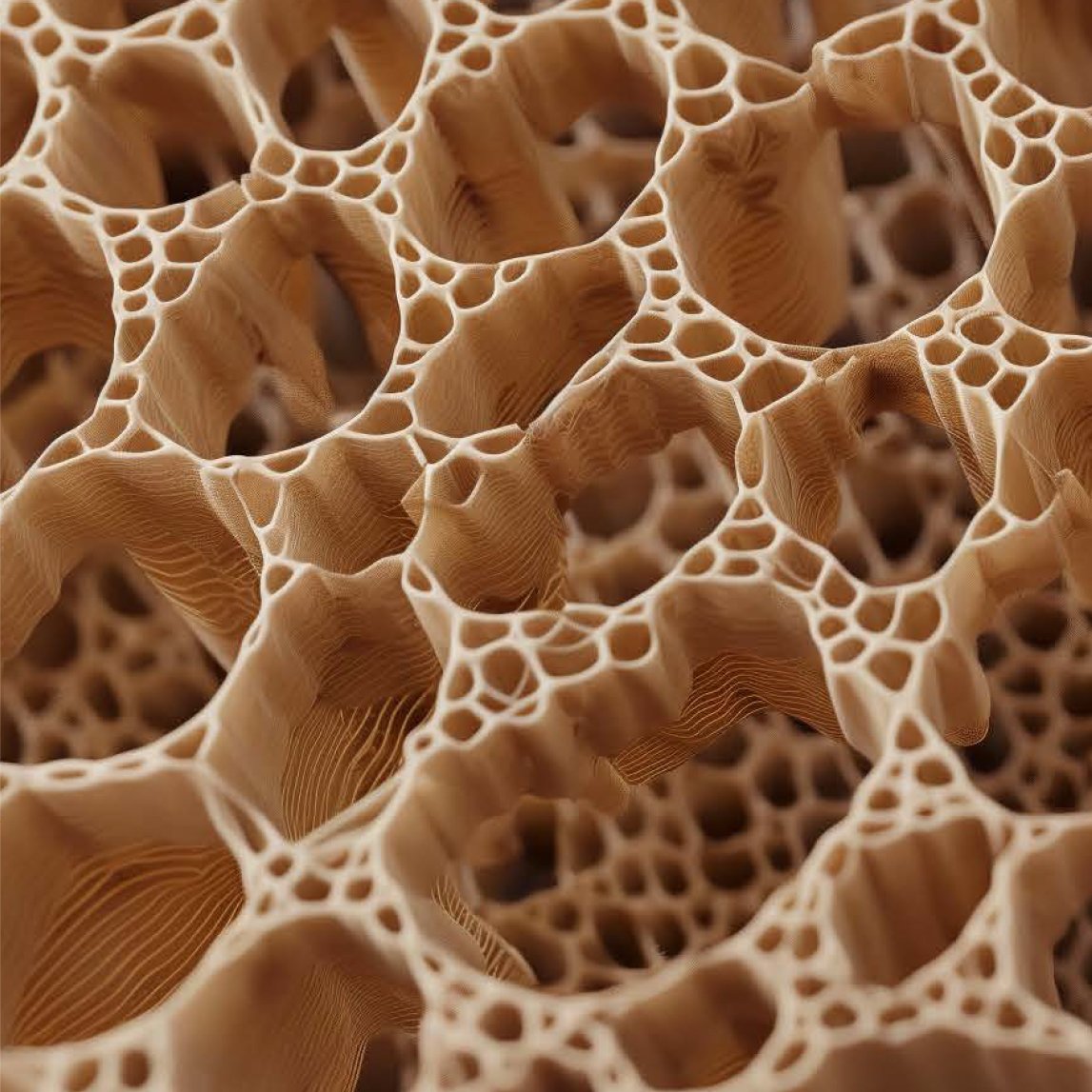

Squeezing wood also costs energy, but way less. We are not breaking molecules either. What is happening though is that all fluids are been removed along with air. Again i knew this from earlier efforts but we never then went the extra mile because the operators saw an opportunity to squeeze western red cedar into thinner hardwood boards.

great product, but not a steel or aluminium replacement. consistency also a problem easily overcome by furthur densification.

invent wood has understood that we can use this to massively replace structural metal of all sorts.

Been densified, application of flame will only char the product and that takes a long time as well...

\

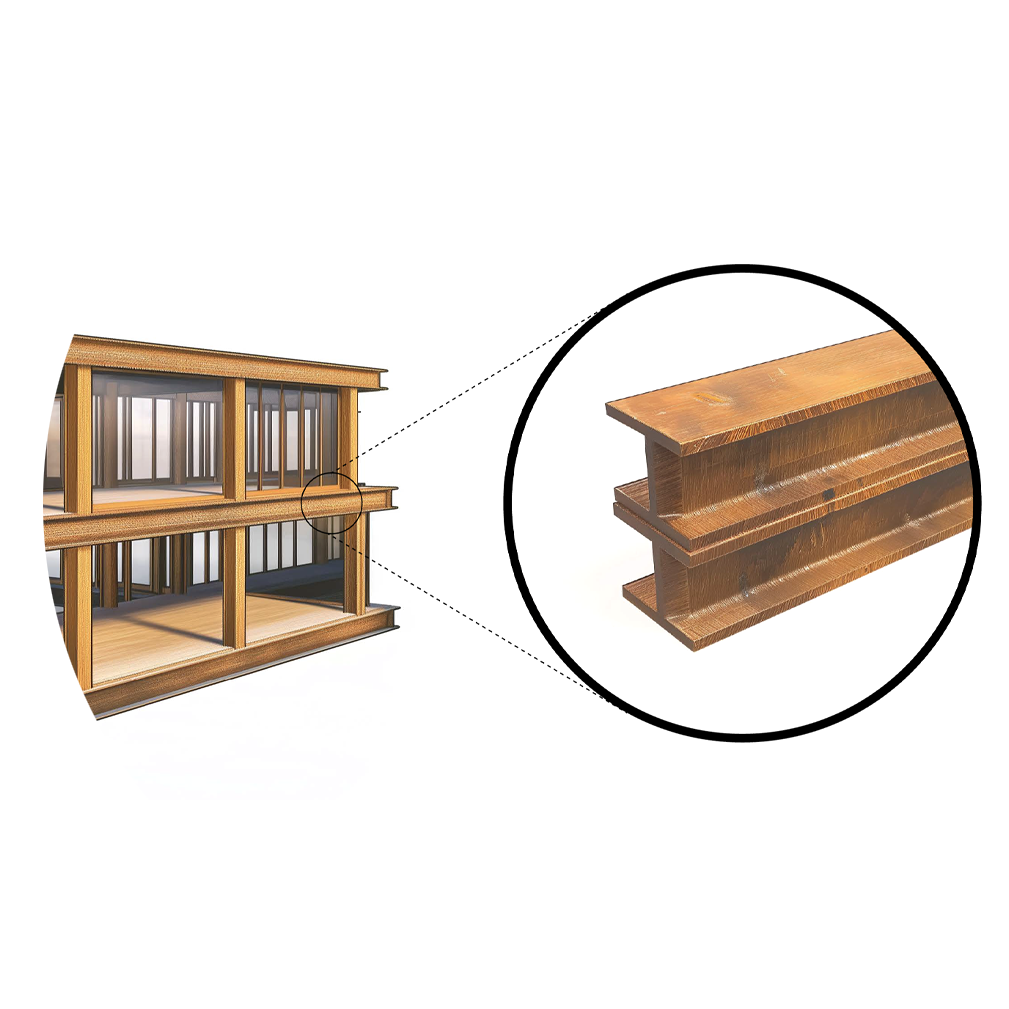

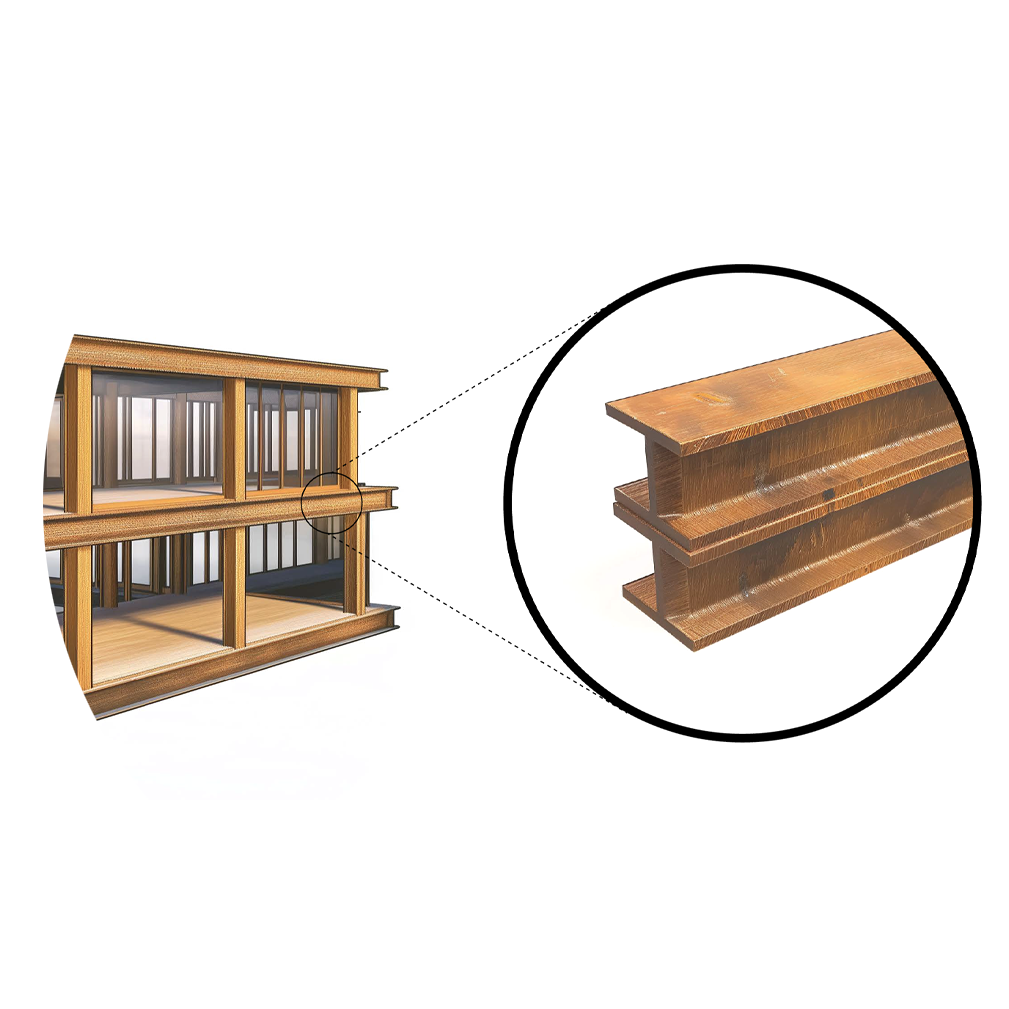

MettleWood

HARNESSING THE STRENGTH OF CELLULOSE

https://www.inventwood.com/mettlewood

MettleWood, our first-to-market material is a biomaterial of unprecedented strength and durability that can replace 80% of all steel and concrete used today.

50% STRONGER THAN STEEL

6X LIGHTER THAN STEEL

This new material is extremely durable, and 100% wood. MettleWood offers higher performance while meaningfully reducing climate-changing emissions.

MettleWood unleashes the strength of cellulose, transforming wood into a new game changing biomaterial that is

80% LIGHTER THAN STEEL

*A36 STEEL

50% STRONGER THAN STEEL*

LESS EXPENSIVE THAN STEEL

CARBON SEQUESTERING

UNPRECEDENTED STRENGTH

MettleWood's unmatched strength-to-weight ratio opens up applications previously unobtainable with wood, with wood, such as those where structural steel is used.

LIGHTWEIGHT

MettleWood is 80% lighter than steel leading to dramatically lower construction and transportation costs, easier handling and installation, and faster building construction.

DURABLE AND FIRE RESISTANT

MettleWood is highly resistant to fire, capable of a Class A fire rating, which will be a first for a 100% wood product. It is also highly resistant to moisture, fungus, termites, scratching, and denting.

COST EFFICIENT

MettleWood has a significantly lower price point than incumbent materials over its complete lifecycle, helping to reduce costs without sacrificing performance.

CARBON-SEQUESTERING

MettleWood can be made with almost any wood including abundant, fast-growing, and even invasive wood species. This flexibility supports greater forest diversity and ecosystem health, allowing for sustainable sourcing and worldwide access.

No comments:

Post a Comment