This is excellent and goes a long way to fulfilling the promise of the wankle engine.It is important because it will knock three quarters of the mass out of the internal combustion engine. This will be really attractive to the agricultural industry.

Electrification is coming to the sweet spot of personal transport. As it should. It puts a premium on light weight and nimbleness which the EV has.

Agriculture does not need speed and likes lots of surplus power and also surplus weight. The other thing everyone is missing is that the market for refined hydrocarbons is going to collapse big time. It is seeing its last hurrah now as a short supply price setter and that is likely fraud.

For that reason deisel will be a convenient cheap agricultural fuel for at least two decades if not a lot longer. Recall we still use steam power to produce electricity. and coal never did manage a real price boom.

"Inside-out Wankel" rotary engine delivers 5X the power of a diesel

By Loz Blain

April 04, 2023

https://newatlas.com/automotive/inside-out-wankel/

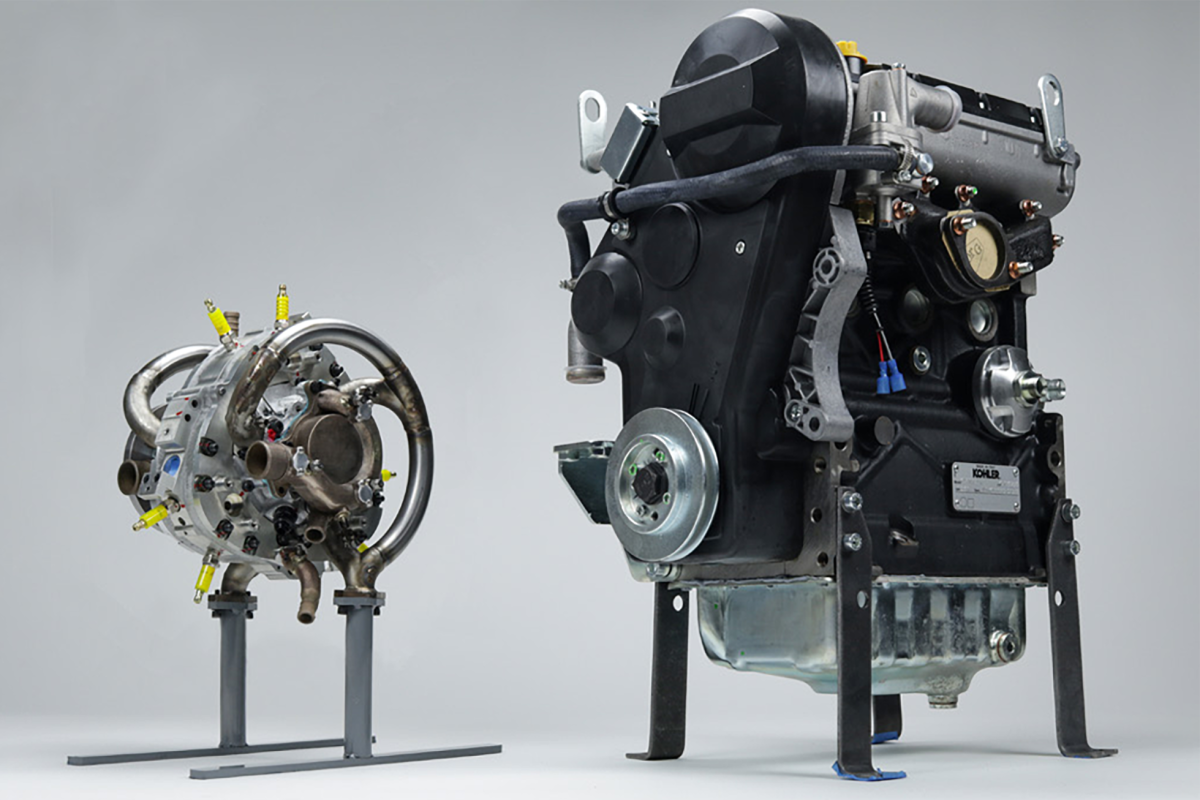

LiquidPiston's XTS-210 is an ultra-portable, multi-fuel capable rotary engine delivering as much power as diesel piston engines five times its size and weight

LiquidPiston says its new XTS-210 solves the efficiency, lubrication and fuel type issues of Wankel rotary engines. This supercharged, liquid-cooled two-stroke claims 5X the power of an equivalent size or weight diesel engine, and 3X the torque.

Targeted at military, commercial and aerospace applications, the XTS-210 is about the size of a basketball, weighs in at 19 kg (42 lb), and displaces 210 cc. It'll run on multiple fuels, including diesel and kerosene/jet fuel. The company is shooting for about 20 kW (26.8 hp) and 29.4 Nm (21.7 lb-ft) of torque, both at 6,500 rpm.

These numbers compare favorably against the 18.8 kW (25.2 hp) and 63 Nm (46 b-ft) peak outputs of the Kohler KDW1003 E536A, says LiquidPiston, a diesel roughly five times the physical size of the XTS-210, and over four times the weight. And the XTS design uses just two primary moving parts: a rotor and a shaft. You can see a breakdown of an older version in the video below.

Liquidpiston X-engine

So how do they work? "If you recall the Wankel," LiquidPiston co-founder and CEO Alec Shkolnik explained to us in a 2020 interview, "they have a triangular rotor inside a peanut-shaped housing. We have the opposite, a peanut-shaped rotor in a tri-lobed housing. So take everything you know about the Wankel and turn it literally inside out.

"They have a long, skinny, moving combustion chamber, we have a stationary combustion chamber that's nice and round. You can drive it to a high compression, just by making the chamber smaller. And because it's stationary, we can directly inject fuel where the Wankel could not. So those are the two key advantages of the diesel: high compression ratio and direct injection.

"And then there's our apex seals, they're like our piston rings. In the Wankel engine, they're inside the rotor, again. They move at a high speed, and bounce around, they're very hard to lubricate. In our case, they're stationary, they don't bounce around, and you can lubricate them directly from the housing.

"So we basically solved the key challenges the old rotaries had with combustion and with oiling. Those oiling challenges caused both durability issues and emissions problems. By making those components stationary, we solve the challenges of the old rotary. And we also upgraded its cycle to give it much higher efficiency."

LiquidPiston X-Engine takes flight [Long]

LiquidPiston has been working on these X-engines for nearly 20 years now, with numerous prototypes already tested in small planes (see above) and go-karts. Other prototypes have included naturally aspirated versions making up to 40 hp, and forced-induction engines up to 70 hp. They've run these things on diesel, gasoline, hydrogen and propane, and they're developing the XTS-210 at the moment on JP-8/Jet-A fuel due to its ubiquity in defense and aerospace.

The company is moving to commercialize the XTS-210 off the back of a US$9-million US Army contract, with a prototype expected for delivery in 2024. This brings LiquidPiston's military contract total over $30 million. Its immediate use cases are expected to be in portable generators and UAVs, although a separate project is evaluating it for use in a hybrid-electric VTOL UAV.

“There are essentially no diesel engines in the 25-horsepower power class today that are suitable for aerospace and mobile military applications, where size and weight parameters are especially critical," said Shkolnik in a press release. "The reduced weight, size, and heavy- or multi-fuel capability of the XTS-210 delivers significant end-system capability and utility benefits, especially for the military to reduce supply chain and logistical burdens in an era where ‘power on the move’ is increasingly important."

The XTS-210 is about the size of a basketball, and makes around 25 peak horsepower

LiquidPiston

As electrification takes off, it's a difficult time to be working on new combustion engine concepts – but the military certainly won't be fully electric any time soon, and the LiquidPiston design's portability and multi-fuel capability could certainly see it through to volume manufacturing if it proves efficient and durable across a wide range of conditions.

No comments:

Post a Comment